Clarifiers / Drive Units > Bridge Mounted Drive Units for Clarifiers & Thickeners

Bridge Mounted Drive Units: Applications & Overview |

|

|

|

Bridge Mounted Drive Units: Primary Features |

|

|

|

Model |

Continuous |

Maximum Overload |

Yield |

|||

ft-lbf |

N-m |

ft-lbf |

N-m |

ft-lbf |

N-m |

|

SX-A* |

3,000 |

4,100 |

6,000 |

8,200 |

8,100 |

11,000 |

SX-B* |

6,000 |

8,200 |

12,000 |

16,400 |

16,200 |

22,000 |

SX-C* |

10,000 |

14,000 |

20,000 |

28,000 |

27,000 |

36,500 |

S25-A* |

14,000 |

19,000 |

28,000 |

38,000 |

54,000 |

73,000 |

S34-A* |

18,500 |

25,000 |

37,000 |

50,000 |

120,000 |

163,000 |

S34-B* |

27,000 |

36,500 |

54,000 |

73,000 |

120,000 |

163,000 |

S44-B* |

35,000 |

47,500 |

70,000 |

95,000 |

195,000 |

264,000 |

S44-C* |

47,000 |

64,000 |

94,000 |

128,000 |

195,000 |

264,000 |

S60-C* |

65,000 |

88,000 |

130,000 |

176,000 |

440,000 |

597,000 |

S60-D* |

125,000 |

169,500 |

250,000 |

339,000 |

440,000 |

597,000 |

S80-D* |

140,000 |

190,000 |

280,000 |

380,000 |

750,000 |

1,017,000 |

S80-E* |

250,000 |

339,000 |

500,000 |

678,000 |

750,000 |

1,017,000 |

S44-B*2 |

70,000 |

95,000 |

140,000 |

190,000 |

390,000 |

528,000 |

S44-C*2 |

94,000 |

128,000 |

188,000 |

256,000 |

390,000 |

528,000 |

S60-C*2 |

130,000 |

176,000 |

260,000 |

352,000 |

880,000 |

1,194,000 |

S60-D*2 |

250,000 |

339,000 |

500,000 |

678,000 |

880,000 |

1,194,000 |

S80-D*2 |

280,000 |

380,000 |

560,000 |

760,000 |

1,500,000 |

2,034,000 |

S80-E*2 |

500,000 |

678,000 |

1,000,000 |

1,356,000 |

1,500,000 |

2,034,000 |

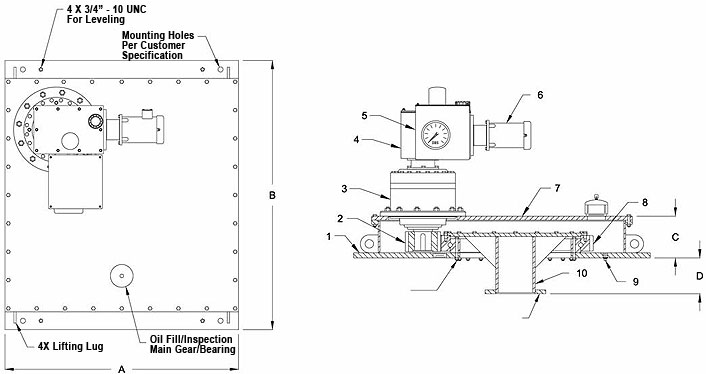

S-Series Details/Dimensions

|

|

Model |

A |

B |

C |

D |

Output Flange |

Weight |

|||||

|

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

lb |

kg |

S25-A |

40 |

1,016 |

48 |

1,220 |

7.5 |

190 |

8 |

203 |

6" |

2,100 |

995 |

S34-A |

48 |

1,219 |

56 |

1,422 |

8 |

203 |

8 |

203 |

8" |

3,000 |

1,364 |

S34-B |

52 |

1,381 |

60 |

1,524 |

9.3 |

236 |

8 |

203 |

8" |

3,200 |

1,455 |

S44-B |

60 |

1,524 |

68 |

1,727 |

9.3 |

236 |

10 |

254 |

10" |

4,000 |

1,818 |

S44-C |

64 |

1,626 |

72 |

1,829 |

11.3 |

287 |

10 |

254 |

10" |

4,300 |

1,955 |

S60-C |

76 |

1,930 |

84 |

2,134 |

11.5 |

292 |

12 |

305 |

18" |

6,400 |

2,909 |

S60-D |

80 |

2,032 |

88 |

2,235 |

13 |

330 |

12 |

305 |

18" |

7,200 |

3,273 |

S80-D |

96 |

2,438 |

104 |

2,642 |

13.5 |

343 |

14 |

356 |

24" |

10,800 |

4,909 |

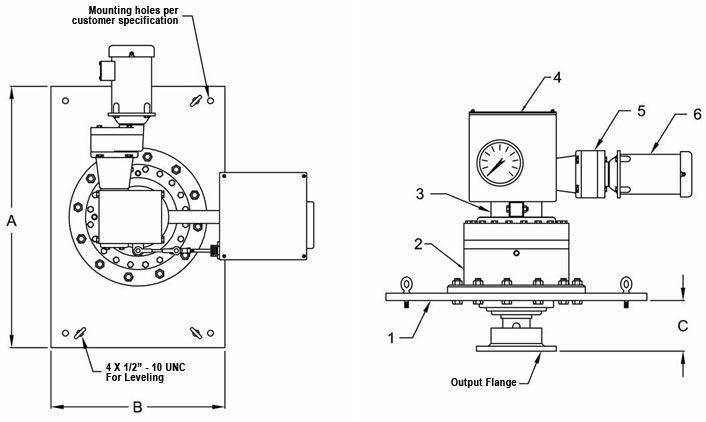

SX-Series Details/Dimensions

|

|

Model |

A |

B |

C |

Output Flange |

Weight |

||||

in |

mm |

in |

mm |

in |

mm |

in |

lb |

kg |

|

SX-A |

36 |

914 |

24 |

610 |

5.2 |

132 |

4" |

700 |

318 |

SX-B |

36 |

914 |

24 |

610 |

7 |

178 |

6" |

900 |

410 |

SX-C |

36 |

914 |

24 |

610 |

8.6 |

218 |

6" |

1,200 |

545 |