Biological Treatment Systems / PVDF Submerged Hollow Fiber MBR Modules

SYSTEM DESCRIPTION

The need to recycle wastewater and more stringent environmental regulations make the MBR system a highly attractive solution for current and future wastewater treatment. Ecologix's Membrane Bio-Reactor Systems are customized to meet these growing demands, and offer the perfect solution for water reuse solutions in both Municipal and Industrial applications.

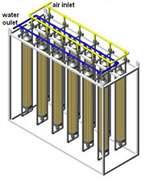

MBR processes produce effluent of high enough quality to be discharged safely to local waterways (coastal, surface, creeks or streams). Additionally the effluent may be reclaimed for urban irrigation. The hollow fiber submerged modules are designed to require a very small footprint. The system integrates hollow membrane fibers, air

inlet pipes, water outlet pipes and aeration pipes into a single module. The system design eliminates the requirement for secondary clarification and tertiary filtration. The aeration tanks will have equal to or less than 5000 mg/l of MLSS making the MBR system a perfect solution for highly efficient treatment using an extremely compact design.

MBR processes produce effluent of high enough quality to be discharged safely to local waterways (coastal, surface, creeks or streams). Additionally the effluent may be reclaimed for urban irrigation. The hollow fiber submerged modules are designed to require a very small footprint. The system integrates hollow membrane fibers, air

inlet pipes, water outlet pipes and aeration pipes into a single module. The system design eliminates the requirement for secondary clarification and tertiary filtration. The aeration tanks will have equal to or less than 5000 mg/l of MLSS making the MBR system a perfect solution for highly efficient treatment using an extremely compact design.

COMPETITIVE ADVANTAGE

PROCESS FLOW DIAGRAM (click to view larger image)

| MBR Product Selection Specs - Model 6040 | ||||||

| Capacity | 25m3/day | 50m3/day | 75m3/day | 100m3/day | 150m3/day | 200m3/day |

| Module Qty | 10 | 20 | 30 | 40 | 60 | 80 |

| Membrane Area (M2) | 160 | 320 | 480 | 640 | 690 | 1280 |

| Water Header Pipe | DN25 | DN32 | DN32 | DN40 | DN50 | DN65 |

| Air Header Pipe | DN32 | DN40 | DN40 | DN50 | DN80 | DN100 |

| Frame SS30 (LxHxW) | 400x2570x1500 | 760x2570x1500 | 1120x2570x1500 | 1480x2570x1500 | 2200x2570x1500 | 2920x2570x1500 |

| MBR Product Selection Specs - Model 6060 | ||||||

| Capacity | 25m3/day | 50m3/day | 75m3/day | 100m3/day | 150m3/day | 200m3/day |

| Module Qty | 6 | 12 | 18 | 24 | 36 | 48 |

| Membrane Area (M2) | 144 | 288 | 432 | 576 | 864 | 1152 |

| Water Header Pipe | DN25 | DN32 | DN32 | DN40 | DN50 | DN65 |

| Air Header Pipe | DN32 | DN40 | DN40 | DN50 | DN80 | DN100 |

| Frame SS30 (LxHxW) | 400x1570x2000 | 760x1570x2000 | 1120x1570x2000 | 1480x1570x2000 | 2200x1570x2000 | 2920x1570x2000 |

MARKET NEEDS/APPLICATIONS