|

Applications Applications |

Automotive Automotive |

Biodiesel Biodiesel |

Dairy Industry Dairy Industry |

Industrial Wastewater Industrial Wastewater |

Food Processing Industry Food Processing Industry |

Iron Removal Iron Removal |

Latex Removal Latex Removal |

Metals Treatment Metals Treatment |

Mining Industry Mining Industry |

Municipal Wastewater Municipal Wastewater |

Odor Control Odor Control |

Petrochemical Industry Petrochemical Industry |

Poultry Industry Poultry Industry |

Products Products |

Activated Carbon Activated Carbon |

Bag Filtration Bag Filtration |

Biological Treatment Biological Treatment |

Chemicals (Specialty) Chemicals (Specialty) |

Clarifiers Clarifiers |

Controls Controls |

Dissolved Air Flotation Dissolved Air Flotation |

Dewatering Dewatering |

Evaporators Evaporators |

Membrane Filtration Membrane Filtration |

Microbial Bacteria Microbial Bacteria |

Oil/Water Separators Oil/Water Separators |

Ozone Ozone |

Pressure Filtration Pressure Filtration |

Screens Screens |

Separators/Strainers Separators/Strainers |

Tanks Tanks |

|

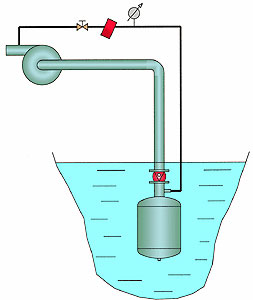

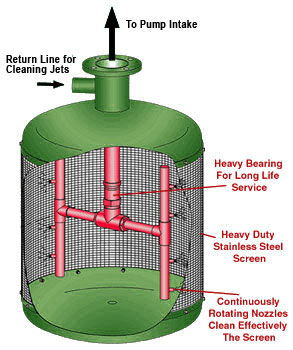

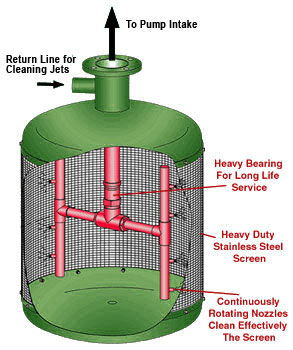

The self-cleaning suction strainer is designed to protect pumps from becoming clogged by debris, trash and solid dirt. It is connected to the pump intake and submerged in the water source (river, lake, stream or other source).

Operation Basics

As the water being pumped flows through the strainer, all the debris is trapped on the screen, protecting the pump from clogging or damage, resulting in increased pump efficiency and reduced maintenance costs.

The screen is kept clean by the continuously rotating jets (using pump pressure through the return line), that sweep away the debris from the screen.

|

Suction Strainer (SS) Series Models / Specifications |

SS-18104 |

4 |

100 |

80 |

352 |

100 |

440 |

SS-18106 |

6 |

150 |

180 |

792 |

230 |

1012 |

SS-18108 |

8 |

200 |

300 |

1320 |

380 |

1673 |

SS-1110 |

10 |

250 |

420 |

1849 |

550 |

2421 |

SS-1112 |

12 |

300 |

600 |

2641 |

750 |

3302 |

SS-18114 |

14 |

350 |

800 |

3522 |

1000 |

4402 |

SS-18116 |

16 |

400 |

1000 |

4402 |

1200 |

5283 |

|

|

Standard Installation example shown below

|

|