Bio-Clear Treatment Systems / Bio-Clear Wastewater Treatment Plant / Bio-Clear FBBR (Fixed Bed Bio-Reactor)

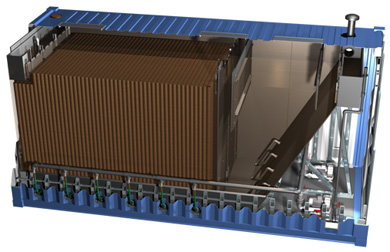

Bio-Clear FBBR fully biological compact wastewater treatment plants in an ISO container The basic concept is the ready-to-operate installation of the plant inside the ISO container, to allow the fastest possible on-site employment. The containers of the compact wastewater treatment plant are manufactured entirely out of weather and wastewater resistant PE plastic. Besides the simple transport of the plant to any place in the world the ISO container also serves to protect the wastewater treatment plant installed above ground against external influences. Therefore, even the most challenging conditions on large-scale building sites do not affect the service life of the plant. This ensures repeated employment. |

|

Special models to meet your requirements Construction sites are often set up in the most remote places, involving special demands on the equipment. In warm regions, sufficient cooling of the biological plant through an appropriate aeration must be assured, arctic conditions require additional heat insulation measures. Our plants have proven their suitability on almost every continent on earth. However, the regional conditions always exert an influence on the conception of the plant. With the modular design principle, special requirements with regard to environmental conditions can be taken into consideration easily by cleverly choosing the plant components. Special solutions with low space requirements are also possible. Here the entire ISO container is lined with a specific steel structure and PE plates to use the full volume of the container as a wastewater treatment plant. For further treatment of primary and excess sludge an additional 20-foot container can be added as separate treatment stage. The sludge is aerated and stabilized, which reduces the amount of sludge. This saves expenses by enlarging the interval for sludge removal. |

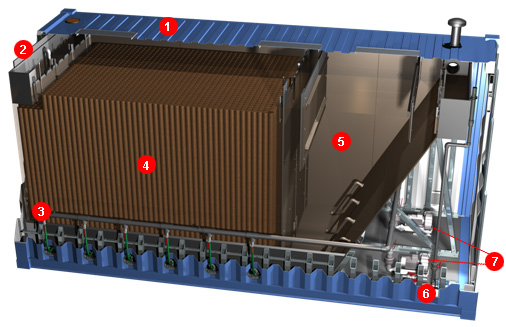

Example of a treatment unit for up to 250 workers - Ecologix Bio-Clear BF-20 |

The Ecologix Bio-Clear FBBR (XL-2 through XL-12

Besides the simple transport of the plant to any place in the world, the ISO container also serves to protect the wastewater treatment plant installed above ground against external influences. Therefore, even the most challenging conditions on large-scale building sites do not affect the service of the plant. |

|

|

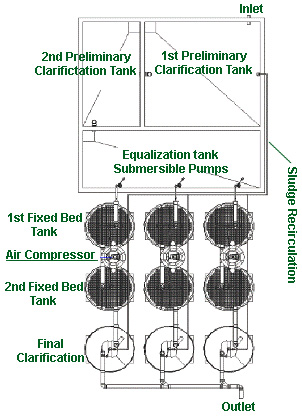

The Ecologix Bio-Clear FBBR XL2-12

|

|

|

Purification Efficiency The wastewater treatment plant container is designed in accordance with DIN 4261 T2, DIN EN 12566-3 or ATV A122, depending on the connection size. With an appropriate dimensioning of the air supply and recirculation, additional nitrification and de-nitrification of the wastewater is possible. The legally stipulated discharge values are met. The operating values of the Bio-Clear FBBR clearly lie below the required limit values. The mean efficiency of the fixed-bed process, for example, is found to be 95.6% for BOD5 and 95.3% for NH4-N. |

|

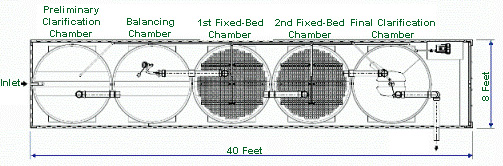

Bio-Clear FBBR Combi XL-2 |

||||||||||||||||||||||||

Bio-Clear FBBR XL-2 through XL-12 The Ecologix Bio-Clear FBBR Combo XL-2 and XL-4 systems (2 x Combo XL-2) the purification stages are also available as a plastic composite construction (PE). Ecologix will provide calculations and drawings for the construction of the preliminary screening stages. In the case of seasonal variations, individual modules may be deactivated without impairing the operational stability of the entire plant. Wastewater-related equipments are fully pre-assembled by the manufacturer so that on-site installation works may be reduced to a minimum. Consolidation of the individual control devices in a central control unit with the possibility of remote monitoring represents a further option which also extends the field of application of our Bio-Clear Combo XL-2 plant and keeps operational efforts as low as possible. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||