|

Applications Applications |

Automotive Automotive |

Biodiesel Biodiesel |

Dairy Industry Dairy Industry |

Industrial Wastewater Industrial Wastewater |

Food Processing Industry Food Processing Industry |

Iron Removal Iron Removal |

Latex Removal Latex Removal |

Metals Treatment Metals Treatment |

Mining Industry Mining Industry |

Municipal Wastewater Municipal Wastewater |

Odor Control Odor Control |

Petrochemical Industry Petrochemical Industry |

Poultry Industry Poultry Industry |

Products Products |

Activated Carbon Activated Carbon |

Bag Filtration Bag Filtration |

Biological Treatment Biological Treatment |

Chemicals (Specialty) Chemicals (Specialty) |

Clarifiers Clarifiers |

Controls Controls |

Dissolved Air Flotation Dissolved Air Flotation |

Dewatering Dewatering |

Evaporators Evaporators |

Membrane Filtration Membrane Filtration |

Microbial Bacteria Microbial Bacteria |

Oil/Water Separators Oil/Water Separators |

Ozone Ozone |

Pressure Filtration Pressure Filtration |

Screens Screens |

Separators/Strainers Separators/Strainers |

Tanks Tanks |

|

Wet Scrubbers / Horizontal Fume Scrubbers

Horizontal Fume Scrubbers are high efficiency, low maintenance scrubbers to remove water soluble contaminants by means of gas absorption or mechanical impingement. These units can be built in either horizontal (crossflow), or vertical (countercurrent) designs, depending on space limitations or layout preference. Our scrubbers can be custom designed with specific parameters such as crossection, packing type and depth, recirculation rate, spray pattern reinforcing based on your exact conditions and the scrubber efficiency required. These scrubbers are constructed according to the highest quality standards in the industry, and are built for maximum corrosion resistance under the most severe duty conditions.

|

Fume Scrubbers - Custom built Fume Scrubbers constructed from PVC, Solid Fiberglass, Filament Wound, CPVC, Polypropylene

The removal of contaminants is accomplished by first slowing the fumes to a velocity below 500 fpm and then passing the fumes through four stages of scrubbing. The fumes pass first through a water spray during which some of the larger contaminant particles drop out and the remaining fumes are saturated. The second stage consists of a 12" deep pack of polypropylene, non clogging, spherical type mass packing which is kept constantly wet by a continuous spray. The saturated fumes are impinged upon the packing and the contaminants are absorbed and carried away in the wash water. After passing through the scrubbing stages, the air is mist laden and must then pass through the two stage gravity mist eliminator section. This consists of a drop out area that removes all but the finest mist, then, a series of vertically mounted PVC eliminator blades provide four 30 degree changes in direction and efficiently eliminates entrained water.

Single pack scrubbers have a static pressure drop of 2" w.g. and extended pack models have a static pressure drop of 3" w.g..

These scrubbers may be supplied with water either directly from your supply or from an integral or remote recirculation system supplied with the scrubber. It is generally recommended that a recirculation system be used to conserve water except on very low cfm units. The actual fresh water consumption varies from only 0.10 to 0.30 gpm/1000 cfm depending on the contaminant involved. This represents 5% of the water being recirculated. If cold conditions exist a remote recirculation system should be specified for placement in a heated area. Ecologix Scrubbers come complete with fittings for the addition of chemical neutralizers if required. A complete metering and pumping system is also available upon request.

Every Ecologix Scrubber is shipped complete with an integral coated steel base. No special mounting is required. Simply connect the duct, the water and power supply, and the unit is ready for operation. Complete installation and operating instructions are supplied with all Scrubbers. Ecologix offers design, fabrication and installation of control panels for completely automated scrubbing systems including conductivity, pH control, fresh water intake, static pressure monitoring and more. |

|

|

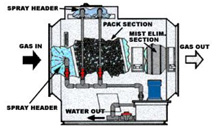

HEDRON HORIZONTAL FLOW FUME SCRUBBER

This four stage scrubber is one of the most popular designs available. This versatile crossflow scrubber is used to remove corrosive or noxious fumes with high efficiency. It may be installed with a remote recirculation system for sub-zero climates.

HEDRON III HORIZONTAL FLOW FUME SCRUBBER

This extended bed unit can be utilized to ensure maximum scrubbing efficiency on low soluble fumes. Hard to remove fumes such as nitric, hydrofluoric, and hydrochloric acids are more efficiently scrubbed with this unit. Both Hedron Series are offered from 500 CFM to 30,000 CFM units. |

|

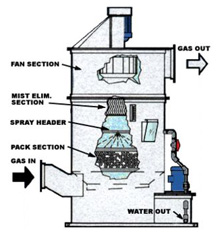

OMNI FAN SCRUBBER COMBINATION

The true economizer in both space and price, and available in both single and double pack units. The outlet can be rotated 360 degrees during installation before being bolted in a fixed position. This vertical flow unit also offers an excellent efficiency equal to the Hedron. This unit is available in the extended bed type. The OMNI Series is offered from 500 CFM to 12,000 CFM units. |

|

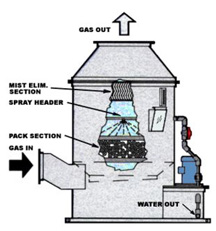

PHASER PACKED TOWER FUME SCRUBBER

One of the first designs in fume scrubbers, this efficient unit allows the use of a stack fan or a centrifugal design fan. If restricted floor space is the problem, the Phaser often solves it. This unit is also available in an extended bed type. The Phaser Series are offered from 500 CFM to 24,000 CFM units. |

| Typical Chemistries and Applications for packed Bed Scrubbers |

Ecologix Fume Scrubbers - Average Removal Efficiencies |

Nitric Acid

Hydrochloric Acid

Hydrofluoric Acid

Sulfuric Acid

Phosphoric Acid

Fluoboric Acid

Acetic Acid

Hydrogen Sulfide

Chromium Compounds

Nickel Compounds

Cadmium

Nitrogen Oxides

Ammonia

Chlorine

Formaldehyde

Cyanide Compounds

Bromine

Hydrogen Bromide

Caustic Solutions

|

All Water Soluble Chemistries Plating Chemistries

Metal Finishing

Semi-Conductor Chemistries

Steel Pickling

Aerospace

Nox Systems

Chemical Manufacturing

Chemical Processing

Anodizing

Etching

Odor Control Systems

Municipal Waste Treatment

Phosphating

Bright Dip

Cleaning

Lab Exhaust

Descaling

Stripping

Electroless Nickel |

| CONTAMINANTS |

HEDRON

PHASER

OMNI |

HEDRON III

PHASER III

OMNI III |

HEDRON V |

PHASER VII |

| |

% |

% |

% |

% |

Acetic Acid (CH COOH) (2)

Alkaline Cleaners (Mist)

Aluminum Bright Dip (3) (4)

Amines (2)

Ammonia (2)

Anodizing (Mist)

Aqua Regia

Boric Acid

Bromine Gas (2)

Caustic Cleaners (Mist)

Chlorine Gas (2)

Chlorine Dioxide (2)

Chromic Acid Plating (Mist)

Copper Chloride

Cyanide Plating Solutions (Mist)

Ferric Chloride (Mist)

Ferric Nitrate

Ferrous Sulfate

Fluoborate (Mist)

Fluorine Gas (2)

Formaldehyde (HCHO) (2) (3)

Hydrogen Bromide (2)

Hydrogen Chloride

Hydrogen Cyanide (2) (3)

Hydrogen Fluoride

Hydrogen Sulfide (2) (3)

Mercaptans (2) (3)

Nickel Chloride (Mist)

Nickel Sulfate (Mist)

Nitric Acid

Nitrogen Dioxide (2) (3)

Nitric-Hydrofluoric Acid

Perchloric Acid (Mist)

Phenol (C H O)

Phosphate Salt Bath

Phosphoric Acid (Mist)

Potassium Dichromate

Sodium Hydroxide (Mist)

Sulfur Dioxide (2)

Sulfuric Acid Pickle (Mist)

Tin Chloride (Mist)

Zinc Chloride (Mist)

Zinc Nitrate (Mist)

Zinc Sulfate (Mist)

|

65

95-97

50-60

55-75

77

95-97

60-70

85-95

20

95-97

35-45

30-40

95-97

75-80

95-97

95-97

95-98

94-97

95-97

38

38

64

66

42

76

55

45

80-85

80-85

63

30-40

60-70

95-97

55

95-97

95-97

95-97

95-98

52

95-97

95-97

95-97

95-97

95-97

|

95

98-99

85-90

85-95

98

98-99

80-90

97-99

47

98-99

73

40-60

98-99

80-85

98-99

98-99

98-99

96-98

98-99

76

77

95

96

80

98

90

80

85-90

85-90

94

50-60

85-90

98-99

90

98-99

98-99

98-99

98-99

90

98-99

98-99

98-99

98-99

98-99 |

98

95

95-98

99

85-95

66

88

60-75

85-90

90

91

98

99

93

99

98

95

90-95

90-95

98

65-80

90-95

98

97 |

99

98

98-99

95-98

82

97

80-90

90-95

98

98

99

99

98

99

98

95-98

95-98

99

80-95

95-98

99

99 |

|

|

|

|

|

|

(1) The efficiencies are intended as representing average values. Specific combinations and concentrations of fumes, type of packing and liquid recycle rates may result in significant variations from the above, therefore no guarantees are implied.

(2) Chemical addition required using PH control.

(3) ORP control required for additional chemicals.

(4) Efficiencies are for the combined nitric acid phosphoric acid fumes. The efficiency for the NO2 portion of the fume is not listed. |

|

|

|