|

Applications Applications |

Automotive Automotive |

Biodiesel Biodiesel |

Dairy Industry Dairy Industry |

Industrial Wastewater Industrial Wastewater |

Food Processing Industry Food Processing Industry |

Iron Removal Iron Removal |

Latex Removal Latex Removal |

Metals Treatment Metals Treatment |

Mining Industry Mining Industry |

Municipal Wastewater Municipal Wastewater |

Odor Control Odor Control |

Petrochemical Industry Petrochemical Industry |

Poultry Industry Poultry Industry |

Products Products |

Activated Carbon Activated Carbon |

Bag Filtration Bag Filtration |

Biological Treatment Biological Treatment |

Chemicals (Specialty) Chemicals (Specialty) |

Clarifiers Clarifiers |

Controls Controls |

Dissolved Air Flotation Dissolved Air Flotation |

Dewatering Dewatering |

Evaporators Evaporators |

Membrane Filtration Membrane Filtration |

Microbial Bacteria Microbial Bacteria |

Oil/Water Separators Oil/Water Separators |

Ozone Ozone |

Pressure Filtration Pressure Filtration |

Screens Screens |

Separators/Strainers Separators/Strainers |

Tanks Tanks |

|

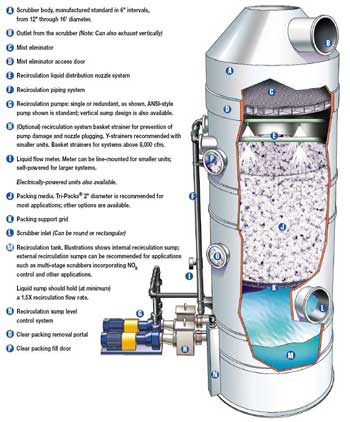

Wet Scrubbers / Vertical Flow Packed Bed

| |

|

Packed Bed Scrubbers are used to remove inorganic gases, odors, fumes and gas streams that contain high pH levels. They are effective for odor removal such as Hydrogen Sulfide, Ammonia, Acetic Acid, Ketones, Amines and Chlorine just to name a few. Packed Bed Scrubbers utilize high mass transfer and liquid recycle rates in order to guarantee adequate chemical is available to absorb odors. |

APPLICATIONS

For gaseous emissions – NOx , Cl2 , SO2 , others For gaseous emissions – NOx , Cl2 , SO2 , others

Acid fumes, including H2 SO4 , HCl , HNO3 , and HF Acid fumes, including H2 SO4 , HCl , HNO3 , and HF

Odor control – single and multi-stage units Odor control – single and multi-stage units

Combination systems for hot and cold gases Combination systems for hot and cold gases

Systems can incorporate particulate control, gas quench, venturis, cartridge filters, and carbon systems. Systems can incorporate particulate control, gas quench, venturis, cartridge filters, and carbon systems. |

Ecologix'

packed bed scrubbers are versatile, reliable

systems that serve the widest variety of processes.

They are used and specified worldwide. Ecologix

packed scrubbers are highly recommended for the

efficient removal of inorganic gases, odors and

fumes, and are particularly appropriate where

gas streams have extreme pH. They are well-suited

for use as primary or secondary systems in conjunction

with thermal oxidizers, and are also used in a

series where there are multiple-contaminant. Optimum

system performance is achieved with systems that

combine intimate gas/liquid mixing and low pressure

drop.

There are four broad categories of information

which influence the design of these systems.

CFM

Air flow through the scrubber, based on cubic

and mist eliminator requirement in microns. ft/min.

This is determined by the process to be provided

by customer and Ecologix analysis. System capacities

of heavy service V/F systems range to 100,000

cfm and above.

Configuration

Internal vs. external recirculation system,

fan location in relation to tower, duct sizes,

inlet and outlet plus location of pump systems,

tower access service ports, service platform requirement.

Materials of Construction

Determined by application; because most

contaminants involve corrosive gases and fumes,

material must be able to withstand continuous

contact with high and low pH gases and scrubbing

solutions.

Operational Efficiency

Removal efficiency of scrubber: inlet vs. outlet

requirement, based on mass emission in lbs/hr. in vs. lbs/hr. out. |

click here to view full cross section of our Tower Scrubber |

Factors to consider in calculating removal efficiency

are:

1. contaminant flow composition

2. contaminant solubility

3. chemistry that will react with contaminants

4. reaction speed

5. HTU (height transfer unit) factors required

for specified removal efficiency

6. liquid-to-gas ratio

7. velocity

|

Producing a Practical

System Design

Using the information gathered under the efficiency

requirement section above, and other factors specific

to the site, Ecologix engineers determine the

optimum tower diameter, packing depth, recirculation

flow rate, and mist eliminator requirement in

microns. |

| V/F 12 |

390 |

1’-0” |

4 - 7 |

10’ - 6” |

V/F 18

|

880 |

1’-6” |

9 - 15 |

11’ - 0” |

| V/F 24 |

1,570 |

2’-0” |

16 - 25 |

11’ - 6” |

| V/F 30 |

2,450 |

2’-6” |

25 - 40 |

11’ - 6” |

| V/F 36 |

3,530 |

3’-0” |

35 - 58 |

13’ - 0” |

| V/F 42 |

4,810 |

3’-6” |

48 - 78 |

14’ - 0” |

| V/F 48 |

6,280 |

4’-0” |

62 - 100 |

14’ - 6” |

| V/F 54 |

7,950 |

4’-6” |

80 - 128 |

15’ - 6” |

| V/F 60 |

9,815 |

5’-0” |

98 - 158 |

15’ - 6” |

| V/F 66 |

11,880 |

5’-6” |

118 - 190 |

16’ - 0” |

| V/F 72 |

14,135 |

6’-0” |

140 - 226 |

17’ - 0” |

| V/F 78 |

16,590 |

6’-6” |

166 - 265 |

17’ - 0” |

| V/F 84 |

19,240 |

7’-0” |

192 - 307 |

17’ - 6” |

| V/F 90 |

22,090 |

7’-6” |

220 - 354 |

17’ - 0” |

| V/F 96 |

25,130 |

8’-0” |

252 - 402 |

18’ - 0” |

| V/F 102 |

28,370 |

8’-6” |

284 - 454 |

18’ - 0” |

| V/F 108 |

31,808 |

9’-0” |

318 - 508 |

19’ - 0” |

V/F 114

|

35,440 |

9’-6” |

354 - 568 |

19’ - 0” |

| V/F 120 |

39,270 |

10’-0” |

392 - 628 |

19’ - 0” |

| V/F 126 |

43,300 |

10’-6” |

432 - 692 |

19’ - 6” |

| V/F 132 |

47,516 |

11’-0” |

475 - 760 |

19’ - 6” |

| V/F 138 |

51,934 |

11’-6” |

519 - 830 |

20’ - 0” |

| V/F 144 |

56,550 |

12’-0” |

565 - 904 |

21’ - 0” |

| V/F 150 |

61,360 |

12’-6” |

614 - 982 |

22’ - 0” |

| V/F 156 |

66,366 |

13’-0” |

664 - 1060 |

22’ - 6” |

| V/F 162 |

71,570 |

13’-6” |

716 - 1145 |

23’ - 0” |

| V/F 168 |

76,970 |

14’-0” |

770 - 1232 |

23’ - 0” |

| V/F 174 |

82,565 |

14’-6” |

825 - 1320 |

25’ - 0” |

| V/F 180 |

88,360 |

15’-0” |

884 - 1412 |

26’ - 0” |

| V/F 186 |

94,345 |

15’-6” |

944 - 1509 |

27’ - 0” |

| V/F

192 |

100,530 |

16’-0” |

1005 - 1608 |

28’ - 0” |

|

External recirculation tank farm. |

Dual fan set up prior to installation of duct. |

Typical upper level access platform interfaced with

existing structure. |

Packed & Tower Scrubbers for Odor Control

|

Odor Control

Odor Control Systems consist of packed bed or packed tower scrubbers, which treat odors such as Hydrogen Sulfide, Ammonia, Acetic Acid, Ketones, Amines and Chlorine just to name a few. Scrubbers utilize high mass transfer & liquid recycle rates in order to guarantee adequate chemical is available to absorb odors.

Ecologix can provide packed bed, packed tower, single stage or multi stage systems for maximum efficiency and tailored to individual process requirements.

Odor control systems include, scrubbers which are complete with high-efficiency extended packed beds, integral mist-eliminator, liquid recycle system including pump(s), integral or remote sump, spray piping with non-clogging spray nozzles, packing and sump access doors. Units are skid mounted, with flanged sections for ease of installation and are available from materials such as PVC, CPVC, Polypropylene, solid FRP or dual laminate. |

Units are provided with chemical holding/storage tanks, chemical metering pumps, probes and analyzers for chemical injection.

Blowers are AMCA (Air Movement & Control Association) rated for performance, completely corrosion resistant, highly efficient and feature smooth, quite operation.

System is complete with its own motor control panel, housed in a NEMA 4X enclosure. Panels are provided with lockable, fused disconnects, push buttons, switches & alarms for air and liquid flow, liquid high and low levels, and are in compliance with the standards of the NEC (National Electric Code) & JIC (Joint Industrial Council). |

|

Typical Application

- Sewage Lift Stations

- Clarifiers, Sludge Dryers

- Municipal Solid Waste

- Lift Stations

- Chemical Processing

- Pharmaceutical Fermentations

- Animal Rendering Plants

- Fish & Poultry Processing

|

|

|

|