|

Applications Applications |

Automotive Automotive |

Biodiesel Biodiesel |

Dairy Industry Dairy Industry |

Industrial Wastewater Industrial Wastewater |

Food Processing Industry Food Processing Industry |

Iron Removal Iron Removal |

Latex Removal Latex Removal |

Metals Treatment Metals Treatment |

Mining Industry Mining Industry |

Municipal Wastewater Municipal Wastewater |

Odor Control Odor Control |

Petrochemical Industry Petrochemical Industry |

Poultry Industry Poultry Industry |

Products Products |

Activated Carbon Activated Carbon |

Bag Filtration Bag Filtration |

Biological Treatment Biological Treatment |

Chemicals (Specialty) Chemicals (Specialty) |

Clarifiers Clarifiers |

Controls Controls |

Dissolved Air Flotation Dissolved Air Flotation |

Dewatering Dewatering |

Evaporators Evaporators |

Membrane Filtration Membrane Filtration |

Microbial Bacteria Microbial Bacteria |

Oil/Water Separators Oil/Water Separators |

Ozone Ozone |

Pressure Filtration Pressure Filtration |

Screens Screens |

Separators/Strainers Separators/Strainers |

Hydrocyclone Separator Hydrocyclone Separator |

Self Cleaning Suction Filter Self Cleaning Suction Filter |

Preliminary Strainers Preliminary Strainers |

Automatic Jet-Disc Filter Automatic Jet-Disc Filter |

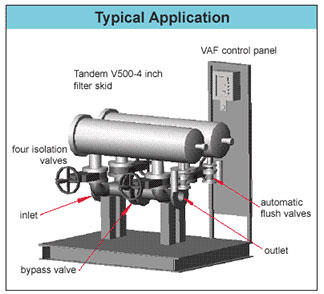

Automatic Jet-Disc Skid Mounted Automatic Jet-Disc Skid Mounted |

Cone Filters Cone Filters |

Tanks Tanks |

|

| the V-Series self-cleaning filters are designed to filter particuate with a limited amount of maintenanc or operation. The Reverser Drive mechanism is a simple design that allows these unique filters to contain fewer moving parts with easy to use controls. |

V-Series

Filters

The V-Series design is the most recent, state-of-the-art

self-cleaning screen filtration technology available

today. The complexity and cleaning efficiency of

any self-cleaning screen filter is in the mechanical

system that drives the cleaning process. The new

V-Series patented "Reverser Drive"

mechanism is the simplest and most efficient in

design resulting in:

- fewer moving parts (no limit switches or

pistons reversing the cleaning mechanism),

- simpler controls,

- reduced flush flow,

- greater cleaning efficiency, and

- lower maintenance requirements.

The V-Series’ 5 to 30 second flush cycle

is automatically initiated when a pressure differential

across the screen increases to 7 psi. The filter

remains on line, and the filtration process remains

uninterrupted during the cleaning process. And

the flush discharge is the lowest in the industry

resulting in minimal waste.

Every filtration project has unique

requirements, so the V-Series filters are constructed

to ASME code and are designed to incorporate a

broad range of construction material, pressure

and temperature options. Ecologix will custom

manufacture filters and skids that simplify installation

and meet specific requirements. Mesh / Micron Data |

V-1000 Schematices.PDF / V-1500 Schematics.PDF |

|

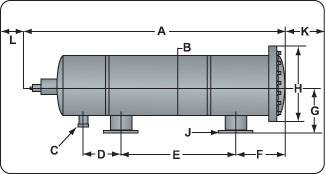

| Model |

Dimensions

- inches |

Screen

Area |

Nominal

Flow

GPM |

Flush

Flow |

#

of

Nozzles |

| A |

B |

C |

D |

E |

F |

G |

H |

J |

k |

L |

in/cubed |

| Length |

Body

Dia. |

Flush

Line |

|

|

|

|

|

Flange |

Clearance |

Clearance |

100µ |

200µ |

300µ |

Gallons |

| V-250 |

38.2 |

10.1 |

1

NPT |

7.1 |

11.5 |

9.4 |

9.2 |

13.5 |

2-3-4 |

30.0 |

12.0 |

224 |

270 |

360 |

400 |

8 |

2 |

| V-500 |

48.3 |

10.1 |

1

NPT |

7.7 |

21.5 |

9.0 |

9.1 |

13.5 |

3-4-6 |

40.0 |

12.0 |

448 |

540 |

720 |

800 |

15 |

4 |

| V-1000 |

60.6 |

15.2 |

2

NPT |

12.5 |

24.0 |

10.5 |

13.4 |

18.8 |

4-6-8 |

56.0 |

12.0 |

867 |

1040 |

1400 |

1520 |

15 |

4 |

| V-1500 |

72.6 |

15.2 |

2

NPT |

12.5 |

36.0 |

16.4 |

18.1 |

29.0 |

6-8-10 |

72.0 |

12.0 |

1300 |

1560 |

2080 |

2280 |

23 |

6 |

| V-2000 |

80.7 |

22.1 |

3

flange |

17.0 |

36.0 |

16.4 |

18.1 |

29.0 |

10-12-14 |

72.0 |

12.0 |

1696 |

2040 |

2720 |

3060 |

33 |

6 |

| V-2500 |

90.0 |

22.1 |

3

flange |

17.0 |

48.0 |

16.4 |

18.1 |

29.0 |

12-14-16 |

80.0 |

12.0 |

2262 |

2710 |

3840 |

4200 |

44 |

8 |

| V-3500 |

118.3 |

24.0 |

3

flange |

34.8 |

50.0 |

16.6 |

20.0 |

31.3 |

14-16-20 |

90.0 |

12.0 |

3060 |

3670 |

4900 |

5360 |

44 |

8 |

| V

Series Specifications |

| Materials |

|

| Filter

Body |

-

2" - 10" inlet/outlet, 316 SS

-10" - 20" inlet/outlet, epoxy coated carbon steel** |

| Screens |

-316L

SS sintered** |

| Flanges |

-AWWA

Class D** |

| Seals |

-

nitrile, viton, silicone |

| Filtraton

Range |

-15

to 1500 micron** |

| Flow

Range |

-35

to 3,670 gpm per filter (with 130 micron screen) |

| Max

Pressure |

-

150 psi (14.2 kg/cm sq.) |

| Min.

Pressure |

-35

psi (2.5 kg/cm sq.) |

| Max

Temp. |

-

176° F (80° C) |

| Flush

Cycle |

-

5 to 30 seconds |

| Control

Options |

-

VF 1B - battery powered, single filter

-VF - AC - electronic, up to 12 filters

-New - fully programmable, electronic, multiple

interface options |

| |

-**

Other options are available |

|

|

|

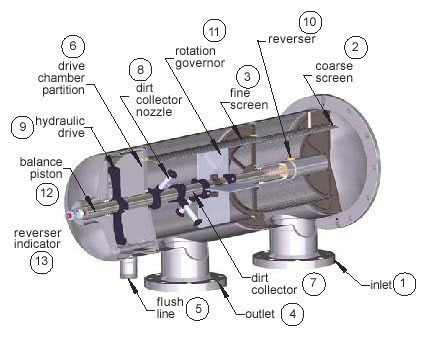

How

the V-Series Self-Cleaning Filters operate:

Dirty water enters the filter through the inlet (1) and then

passes through the coarse screen (2) from the outside in. It

flows from the inside of the coarse screen to the inside of the fine screen and

then passes through the fine screen (3) from the inside out.

Dirt is collected on the inside surface of the fine screen. The clean filtered

water then exits through the filter outlet (4) and on to the

system. As the dirt or cake builds up on the inside surface of the fine screen,

the pressure drop across the screen increases. When the pressure drop, (the DP

or differential pressure) reaches a preset level (7 psi), the filter controller

starts a flush cycle by opening a flush valve on the flush line (5).

This flush valve exhausts the drive chamber to atmosphere at “0” psi.

The flush line (5) is connected to the drive chamber which is

separated from the filtration chamber by a drive chamber partition (6).

However, the dirt collector (7) (a hollow pipe with dirt collector

nozzles) extends through the partition (6), thus providing a “path” from

the dirt collector nozzles (8) through the hydraulic drive (9),

into the drive chamber and out the flush line (5) to atmosphere.

The pressure around the dirt collector nozzle (8) is the pressure

inside the filter and as water flows through the “path”, it drops

to “0” psi when it leaves the flush line (5).

This creates an aggressive “suction” at the dirt collector nozzle

(8) opening. The dirt collector nozzle (8)

clearance at the fine screen (3) is very small. So, the extreme

low pressure at the nozzle opening creates a backflow which “sucks” the

dirt from the fine screen (3). |

The

hydraulic drive (9) has jets

on opposite sides near it’s ends. Water

jetting out of these openings (coming from the

dirt collector nozzles (8) creates

a reaction force (like a pin wheel) which rotates

the drive (9) and the dirt collector (7). As

the dirt collector (7) rotates, each dirt collector

nozzle (8) cleans a band on the fine screen (3).

As the dirt collector (7) rotates, the reverser

(10) (works like the level winder on your fishing

reel) causes the hydraulic drive (9) / dirt collector

(7) / dirt collector nozzle (8)

assembly to move back and forth.

The rotation

governor (11) helps control the rotation speed

of the dirt collector (7) assembly. The balance

piston (12) helps balance the transverse pressure

on the assembly, and powers the reverser indicator

(13) which provides visual indication of the dirt

collector (7) assembly movement showing that the

entire cleaning system is operating properly during

the rinse cycle.

After a preset time, the flush valve closes

and the rinse cycle is complete. Very little

rinse water is used for each rinse. Please note

the filter continues to supply water to the system

during the rinse cycle. |

|

|