Chemical Feed Skids / Chemical Feeders

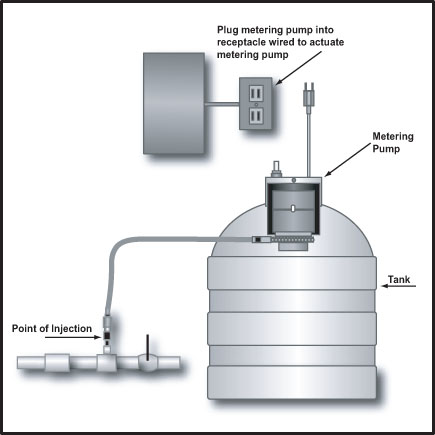

Chemical feeders are used in a great number of applications to inject metal precipitants, coagulants, chlorine into wastewater just to name a few. Chemicals are often injected to raise, lower or maintain pH levels as well as to remove certain elements from the waste stream prior to filtration or storage.Pre-Assembled

Tank for easy installation:

|

|

| Tank and Single Head - Adjustable - 25 psi / 1.7 bar | |||||||

| Tank / Pump | Pump Tube | Max GPD | Output LPD | Tank / Pump | Pump Tube | Max GPD | Outlet LPD |

| STSN45M1 | #1 | 3.0 | 9.1 | STSN85M1 | #1 | 5.0 | 15.1 |

| STSN45M2 | #2 | 10.0 | 30.3 | STSN85M2 | #2 | 17.0 | 51.5 |

| STSN45M3 | #3 | 22.0 | 66.6 | STSN85M3 | #3 | 40.0 | 121.1 |

| STSN45M4 | #4 | 35.0 | 106.0 | STSN85M4 | #4 | 60.0 | 181.7 |

| STSN45M5 | #5 | 50.0 | 151.4 | STSN85M5 | #5 | 85.0 | 257.4 |

| Tank and Single Head - Adjustable - 25 psi / 1.7 bar | |||||||

| Tank / Pump | Pump Tube | Max GPD | Output LPD | Tank / Pump | Pump Tube | Max GPD | Outlet LPD |

| STSN45MHP2 | #1 | 3.0 | 9.1 | STSN85MHP5 | #1 | 5.0 | 15.1 |

| STSN45MHP10 | #2 | 10.0 | 30.3 | STSN85MHP17 | #2 | 17.0 | 51.5 |

| STSN45MHP22 | #7 | 22.0 | 66.6 | STSN85MHP40 | #7 | 40.0 | 121.1 |

| All models are available in UV Gray for outdoor use, and natural translucent for indoor use | |||||||

|

Note: The STS Tank System comes with screws installed into each side of the mounting bracket to prevent shipping damage. Please remove these fasteners upon installation so that the pump may be removed from the mounting bracket when required. |

| DO | DO NOT |

| •

DO check outlet with volt meter before connecting

pump power cord. This can prevent motor burn out

from over voltage.

• DO mount the pump in a dry location on wall to avoid any risk of washdowns allowing water in the openings of the motor. • DO use a rain roof to prevent water or debris intrusion on outdoor applications and indoor industrial job sites. • DO connect the metering pump to the same electrical circuit as the pool or well pump. This will stop metering pump operation and prevent over feeding in the event of an electrical malfunction. • DO install pump according to the installation instructions provided. STS Series pumps properly installed and maintained provide a limited amount of protection from siphoning. Dependent on state or local building codes and system piping configurations, auxiliary devices may be required. • DO use the proper product to treat potable

water supply system. Chemicals should be approved

or listed for use with potable water. |

•

DO NOT use thread seal tape or pliers on tube fittings.

• DO NOT apply any type of lubrication grease, oil, silicone or vaseline to the tube assembly. Lubrication is not needed and some lubricants are incompatible with the plastic parts. • DO NOT mount the pump vertically with the tube housing pointing up because chemical damage will occur in the event of leakage or tube rupture. • DO NOT install the unit directly over an open solution tank. Chemical fumes can damage the metering pump. Solution containers should be kept covered or closed • DO NOT mount the metering pump on any flammable surface. • DO NOT mix chemicals in the solution tank while the metering pump is running. Keep the suction line away from the bottom of the solution container to eliminate residue pickup and possible clogging. • DO NOT operate the metering pump before the chemical is completely in solution. Follow the chemical manufacturer’s instructions for mixing. Soda Ash must be kept agitated continuously with a mixer tank. • DO NOT install the metering pump in a

way that will allow a possible cross connection

of a non-potable water source to potable water

source. |